API Cast steel swing check valve

- Brand: feiqiu

- Standards: API 6D, ASME B16.34, BS 1868

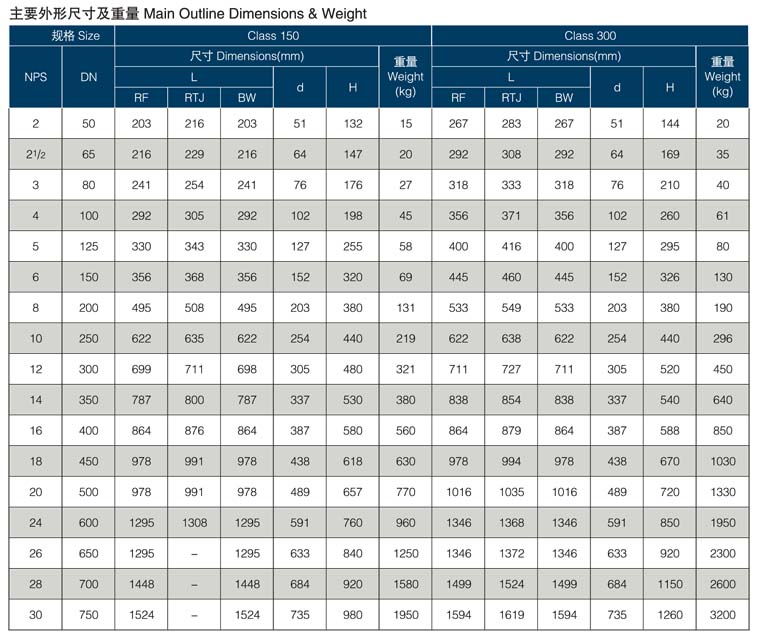

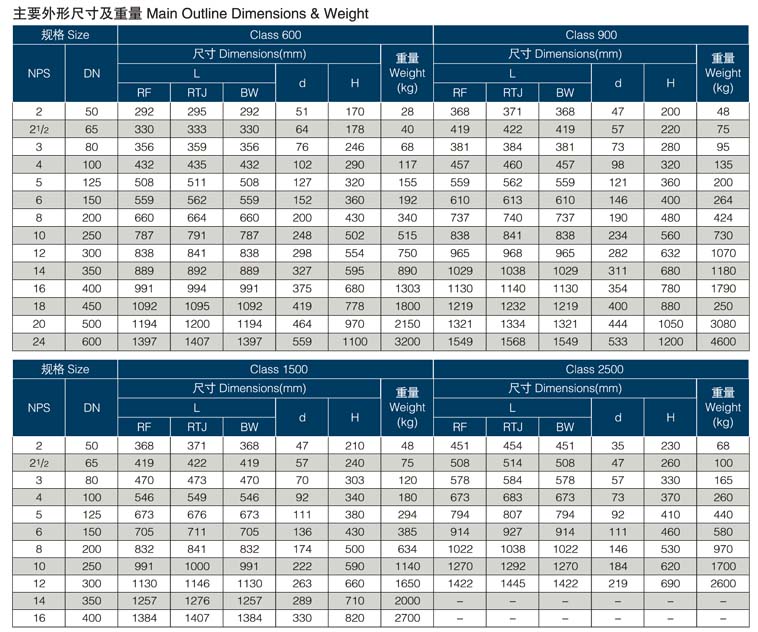

- Class: class150~class2500

- Size: 2

- Material: WCB, S.S. etc.

- Medium: WOG and other corrosive medium.

Brief introduction:

Application standards:

Design and manufacture: API Cast steel swing check valve according to BS 1868, ASME B16.34 and API 6D;

Inspection and test: API 598 or API 6D

End flange dimension: ASME B16.5 (for NPS<24), ASME B16.47 series B, API 605 or ASME B16.47 series A, MSS SP-44 (for NPS > 24)

BW end dimension: ASME B16.25.

Socket-weld dimension: ASME B16.11.

Face to face and end to end: ASME B16.10.

Pressure-temperature ratings: ASME B16.34

Shell wall thickness: API 600 and BS 1868

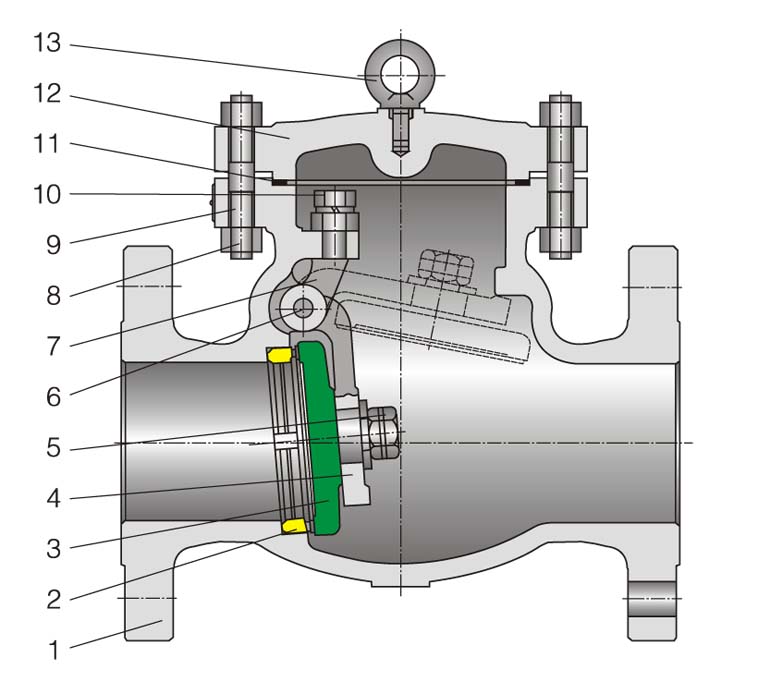

The Features of Check Valve: Bolted Bonnet; Swing and lift disc; Metallic seating surfaces;

Body and Bonnet Connection: Class150-Class900 check valves are usually bolted bonnet, Class1500-Class2500 check valves are usually pressure seal bonnet design;

Seat feature: For carbon steel check valve, the seat is usually forged steel. The seat sealing surface may be spray-welded with hard alloy if specified by the customer. The renewable threaded seat is used for NPS≤10" check valves, and the welded type seat can be also optional if being requested by the customer. The welded type seat is used for NPS≥12" carbon steel check valves. For Stainless steel check valve, integral seat is usually adopted, or it can be machined integrally after hard alloy welded. The threaded or welded type seat is also optional for stainless steel check valve if being requested by the customer.

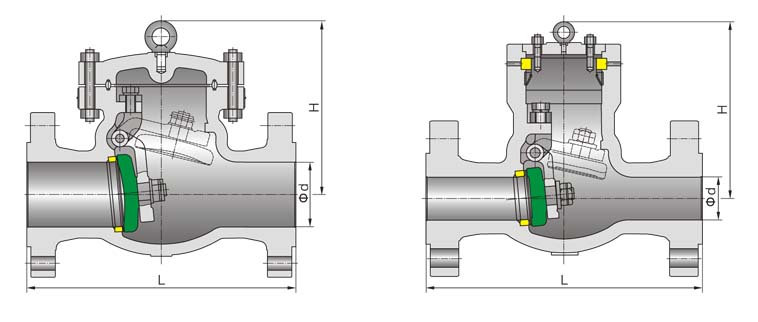

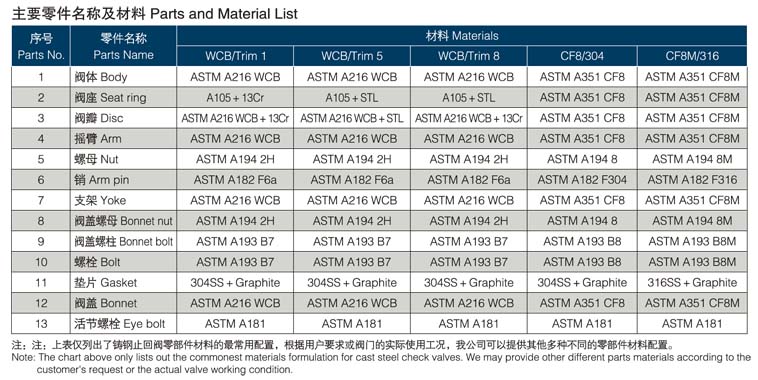

Structural drawing and the material of main parts:

Main outline dimensions: