API cast steel gate valve

- Brand: feiqiu

- Standards: API 6D, API 600,API 603

- Class: Class150~Class2500

- Size: 1/2

- Material: WCB, Stainless steel etc.

- Medium: WOG

Introduction:

Standards:

Design and Manufacture: Cast steel gate valve to API 600 (ISO 10434) or API 6D; Cast stainless steel gate valve to API 603 or API 600;

Forged steel gate valve to API 602.

Inspection and Test: API 598, API 6D.

End flange dimension: ASME B16.5 (for NPS<24), ASME B16.47 series B, API 605 or ASME B16.47 series A,

MSS SP-44 (for NPS>24).

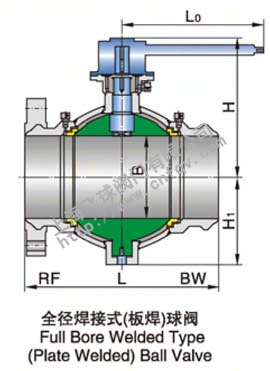

BW end dimension: ASME B16.25.

Socket-weld dimension: ASME B16.11.

Face to face and end to end: ASME B16.10.

Pressure-temperature ratings: ASME B16.34.

Bonnet Gasket Style:

Stainless steel and graphite combined gasket is used for Class 150 gate valve; Stainless steel and graphite wounded gasket is used for Class 300 gate valve; Stainless steel and graphite wounded gasket is used for Class 600 gate valve, and metal ring gasket is also an optional for Class 600 gate valve; Metal ring gasket is used for Class 900 gate valve; Pressure seal design is used for Class 1500一Class2500 gate valve.

Packing Seal:

As usual, flexible graphite is used for packing material. PTFE or combined packing material can be also used if being requested by the customer. The surface roughness between the packing and packing seat is Ra 3.2 u m so that the stem contact the packing surface tightly but rotate freely. The roughness of stem sealing face is Ra 0.8 N m after being precisely machined to ensure the reliable tightness.

Body and Bonnet Connection:

Class 150一Class 900 gate valves are usually used to bolted bonnet design. Class 1500一Class 2500 gate valves are usually used to pressure seal bonnet design

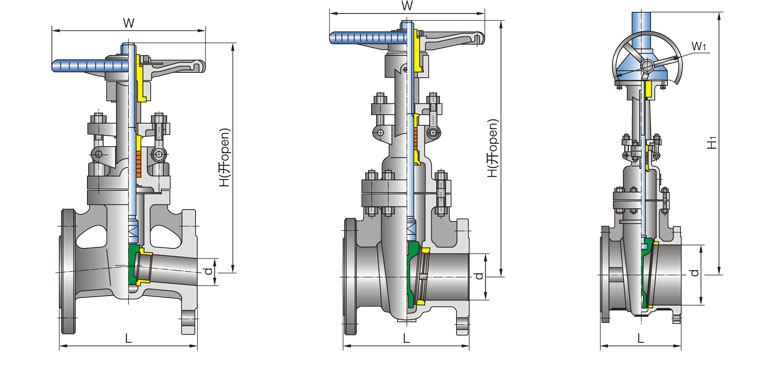

Operation mode:

Handwheel or bevel gear is usually used for gate valve operation. Chain wheel and electric actuator can be also used for gate valve operation if being requested by the customers.

Disc Design:

NPS≥2" API Gate valves are flexible wedge gate; NPS<2" Gate valves are solid gate

Backseat Design:

All Feiqiu gate valves have backseat design. In most cases, the backseat of carbon steel gate valve is renewable. For stainless steel gate valve, the backseat is machined directly on the bonnet or it is machined after welding. When the gate valve is at fully open position, the sealing of backseat can be very reliable.

It is not advisable to replace the packing when the valve includes pressure though API 600 has the backseat explanation.

Stem Design:

The stem is integral forged design. The minimum diameter of the stem shall be as per the standard requirement. The connection of the stem and disc is T type. The strength of the connecting area is bigger than that of the stem T threaded part. The strength test of that area conforms to API 591

Stem Nut:

Usually, the stem nut is made of ASTM A439 D2. It is also can be made of Cu alloy or other materials if being requested by the customer

For large sized gate valves (NPS≥10" Class150; NPS≥8" Class300; NPS>6" Class600; NPS>5" Class900), rolling bearing is fitted between stem nut and stem in order to minimize the torque for easy operation.

Seat:

For carbon steel gate valve, the seat is usually forged steel. The seat sealing surface is spray welded with hard alloy that specified by the customer.

The renewable threaded seat is used for NPS≤10“ gate valves, and welded on seat can be also optional if being requested by the customer.

Welded seat is used for NPS< 12” carbon steel gate valves. For stainless steel gate valves, the seat is integral with body or it can be machined directly

after hard alloy welded.

The renewable threaded seat or welded type seat is also optional for stainless steel gate valve if being requested by the customer.

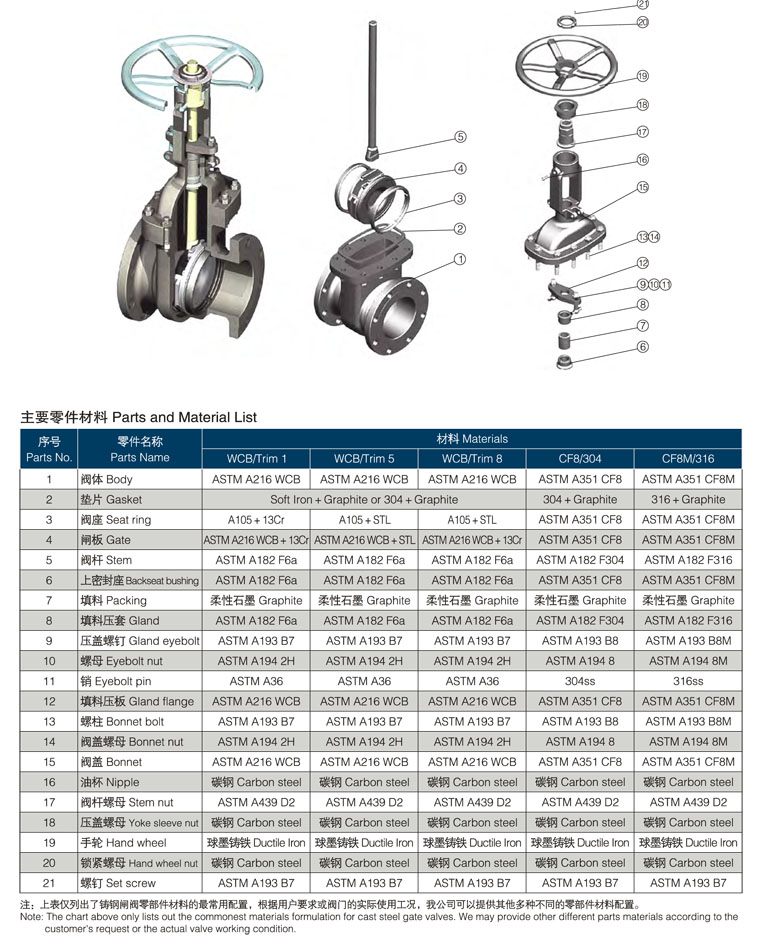

Parts and material list:

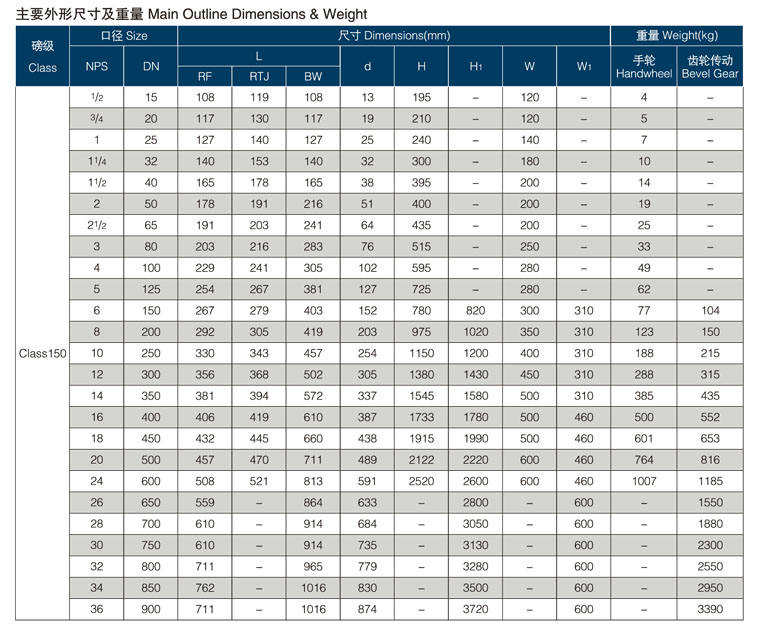

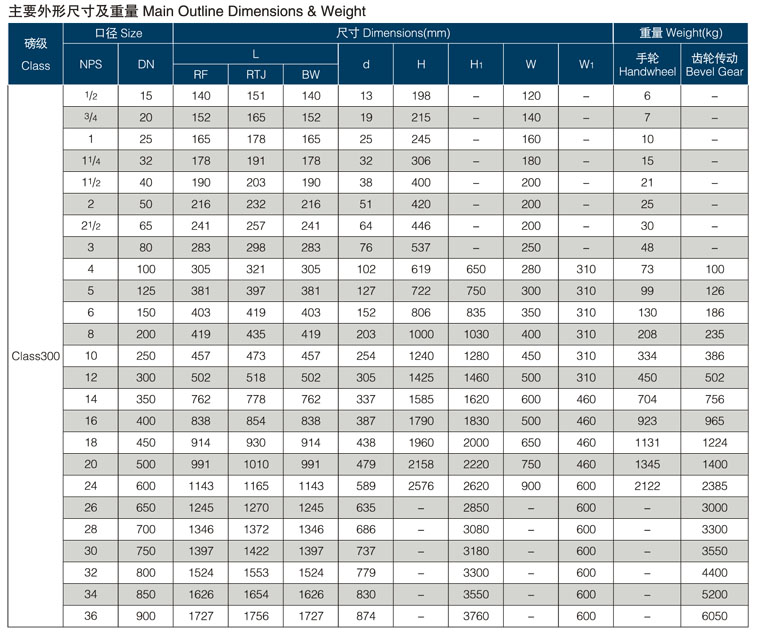

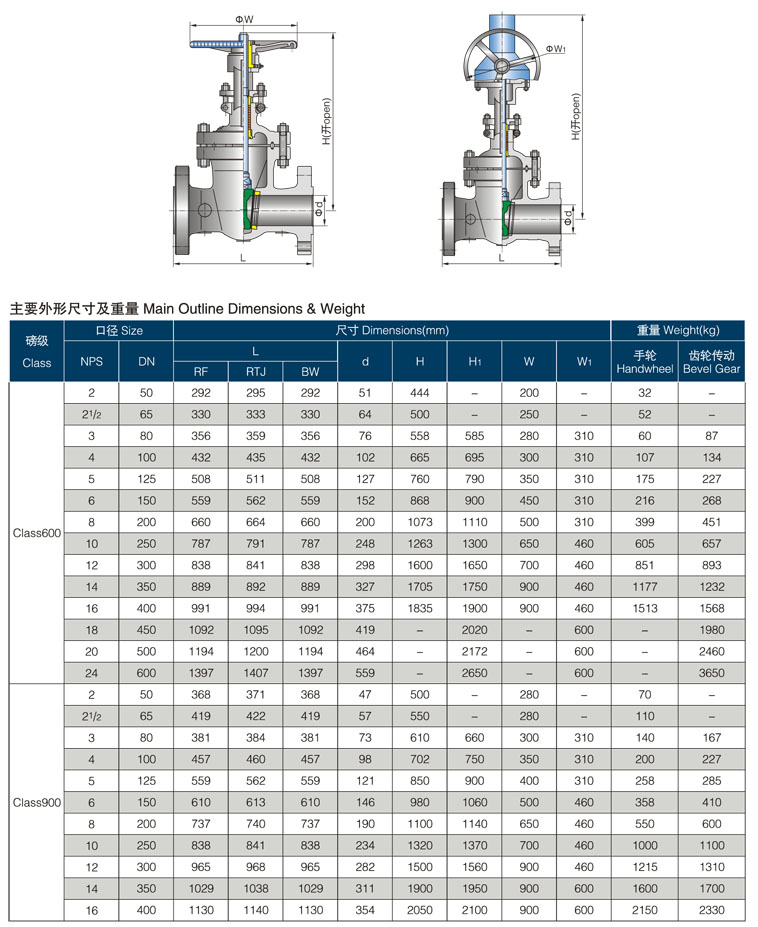

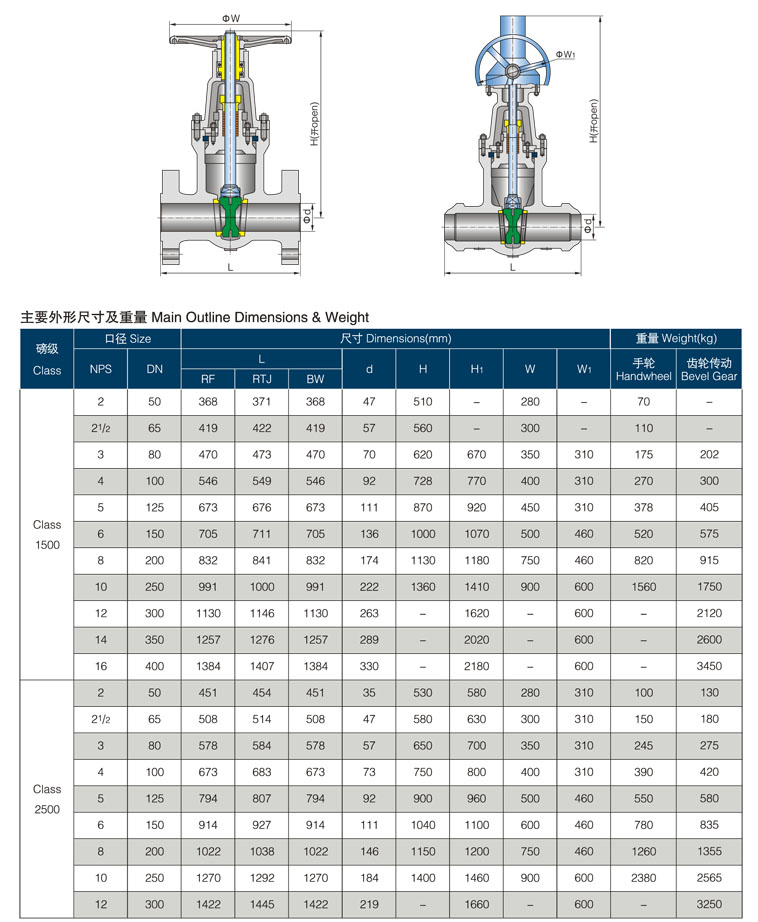

Main connection dimension: